See Full Size

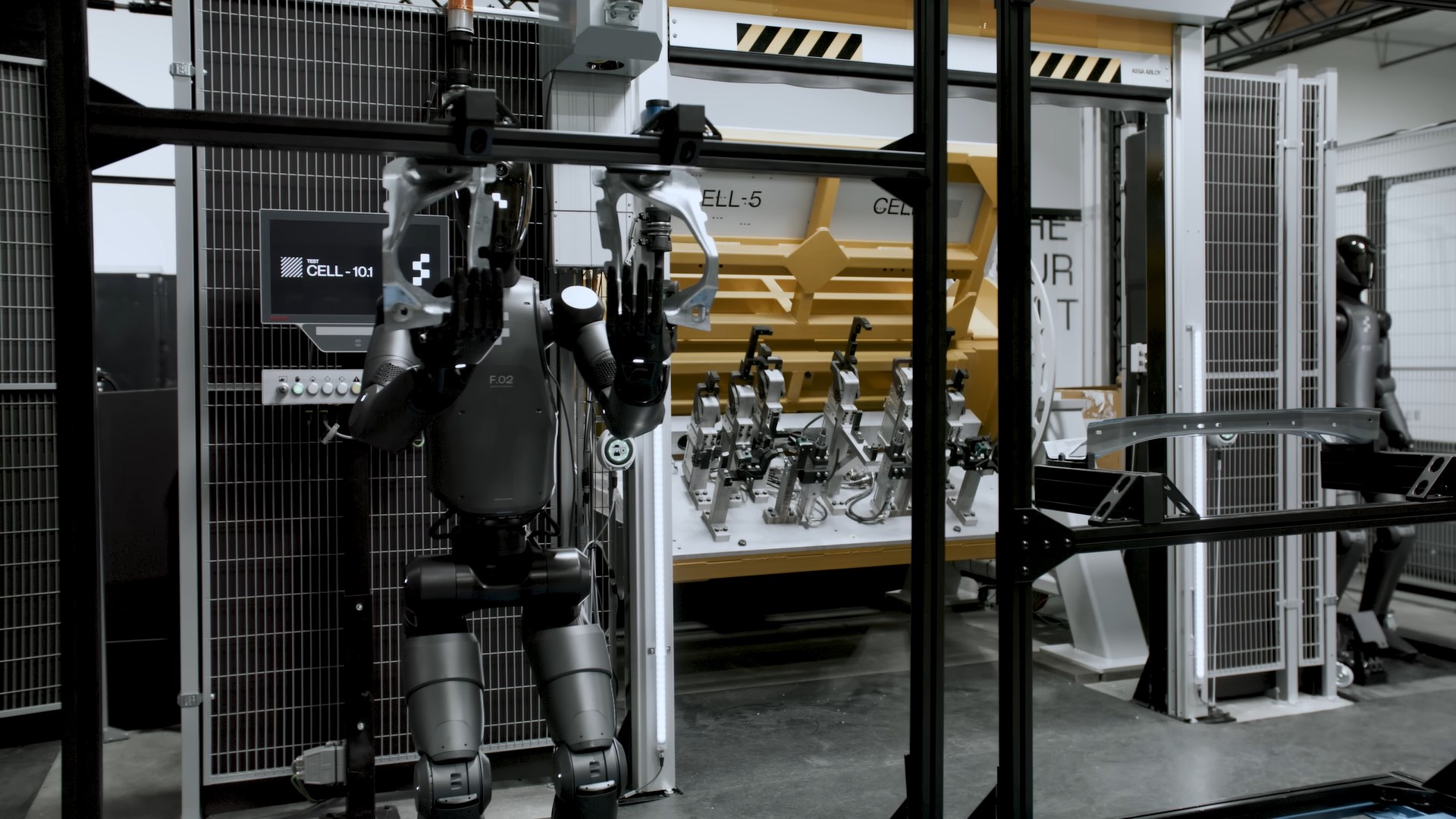

Figure 02 is now faster

See Full Size

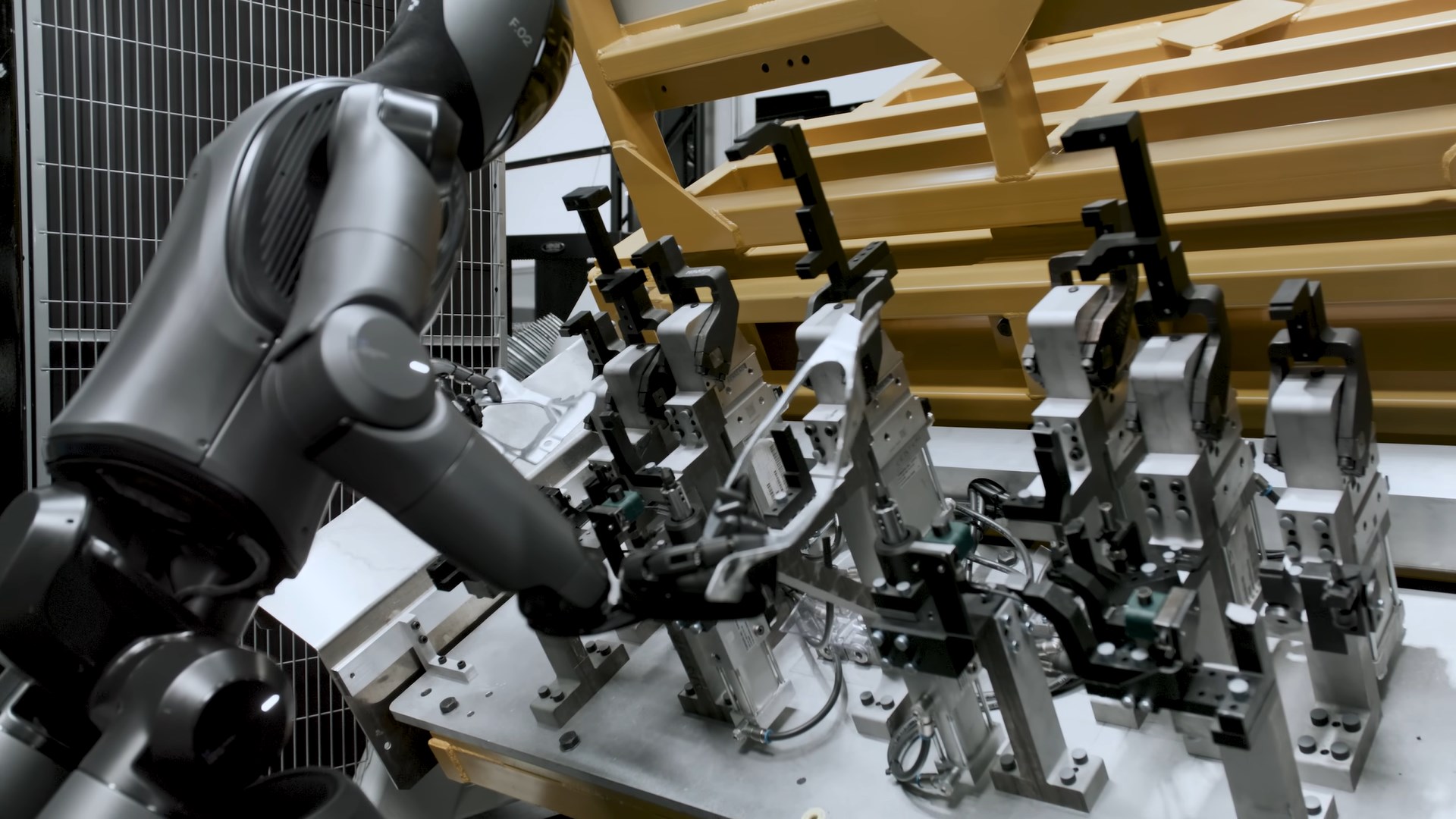

The video also shows the humanoid robot placing a high-precision sheet metal onto a pin post less than 1 cm wide. Adcock said the use case is extremely difficult to deploy autonomously with a high degree of reliability. He also emphasized that the processing time should be shortened by four minutes, reducing the robot’s margin of error to zero in this process.

See Full Size

BMW and Figure AI started their collaboration earlier this year and carried out the first tests at the BMW factory in Spartanburg. Figure 02 It was introduced about 3 months ago. Figure 02, whose hardware and software were completely redesigned, made advances in critical technologies such as artificial intelligence, computer vision, batteries, electronics, sensors and actuators. Figure 02 has the ability to speak to humans in natural language through built-in microphones and speakers connected to custom AI models trained in partnership with OpenAI. The robot’s human-scale hands have 16 degrees of freedom, enabling a wide variety of human-like tasks.

This news our mobile application Download using

You can read it whenever you want (even offline):