See in full size

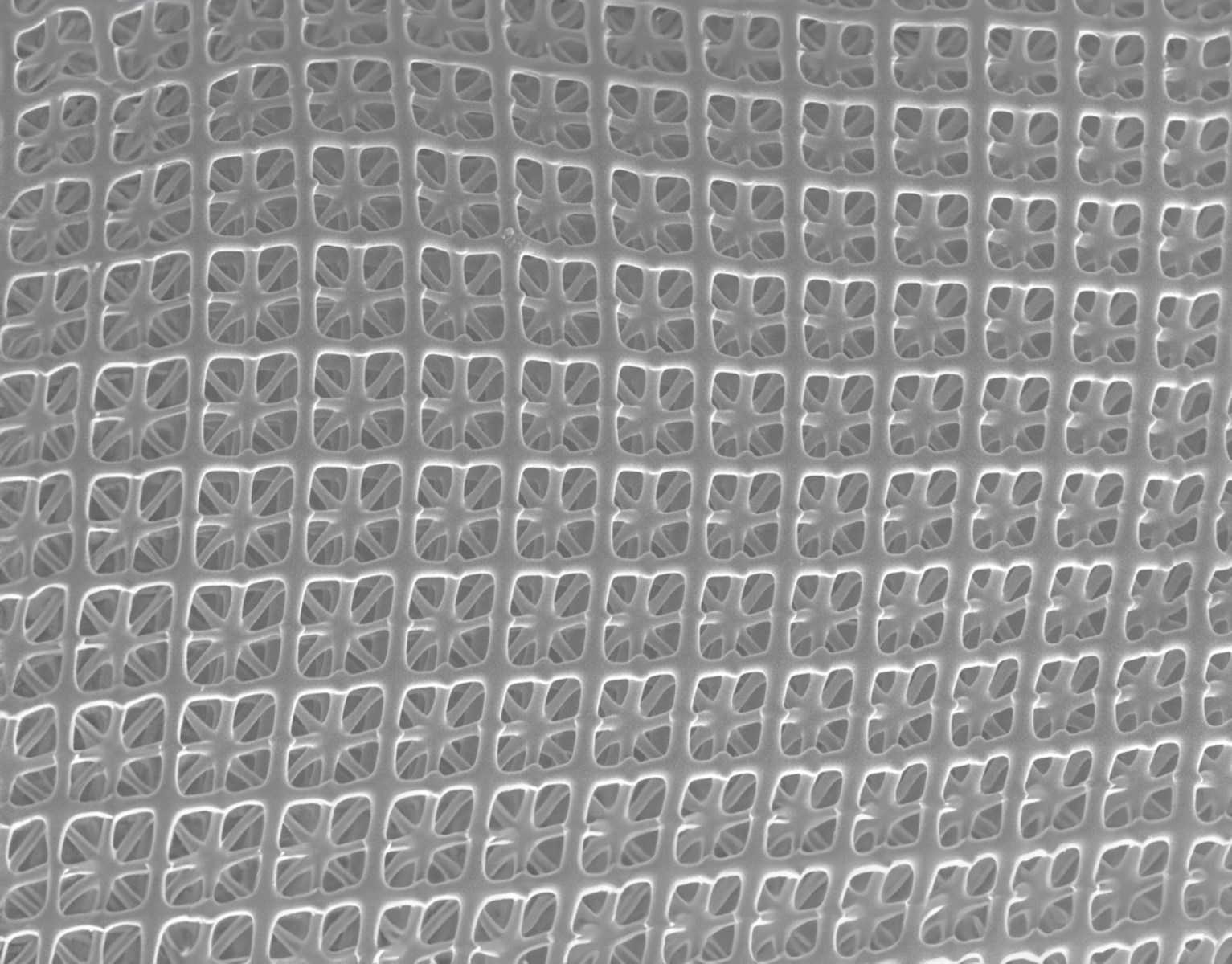

Professor Tobin Filleter team, led by the team, Extraordinary strength, lightness and customizability He managed to design nanomalzemes. These materials consist of only a few hundred nanometers recurrent small building blocks. To compare, when 100 of them are lined up side by side, a person can reach the thickness of the hair strand.

5 times stronger than titanium

The team used the multi-purpose Bayesian Optimization Algorithm to optimize stress distribution of nano-square structures and increase durability. While this algorithm required only 400 data points, more than 20,000 data may be required in traditional methods. Thus, it was possible to work effectively with a smaller but high quality data set.

See in full size

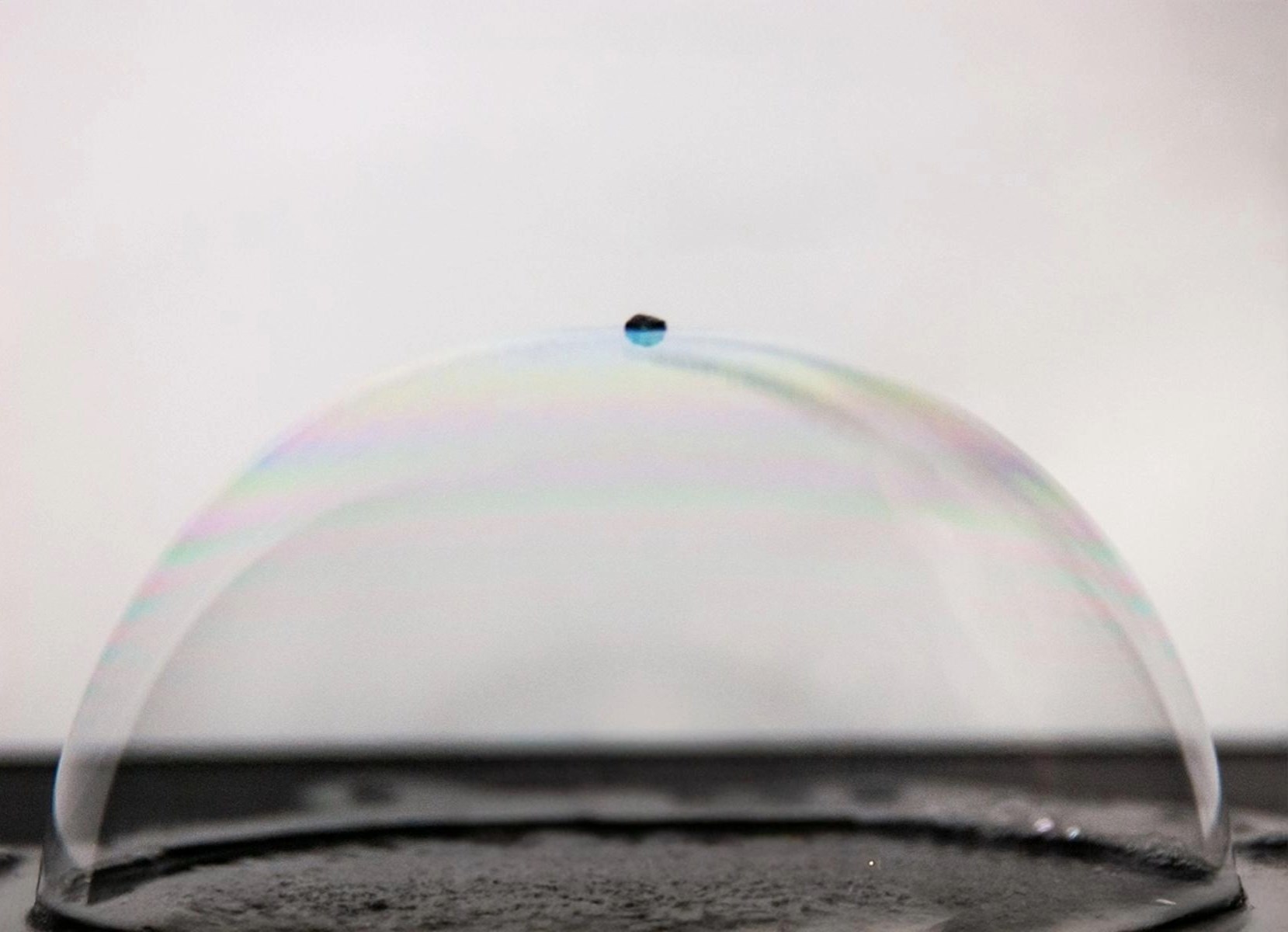

Researchers for experimental verification using two photon polymerization 3D printers Produced prototypes. As a result, optimized carbon -based nano materials, existing designs Double the durability and in the durability per intensity Five times stronger than titanium it has become.

Potential in aviation and automotive

Professor Filleter says these new materials can be used to produce ultra -light components in aircraft, helicopters and spacecraft. According to the researchers, the replacement of titanium components used in an aircraft with this new material can save 80 liters of fuel per year per kilogram. This has the potential to significantly reduce the carbon footprint of aviation. Similarly, the use of the automotive industry will reduce the weight of the vehicles and will allow the range to increase.

This news, Our mobile application download and download,

You can read at any time (even offline):