See Full Size

New cooling solution for processors

In laboratory tests, this new material outperforms commercial liquid metal cooling products such as Thermalright and Thermal Grizzly. outperformed by 56 percent to 72 percent. According to what is reported, the material was collected from an area of only 16 square centimeters. 2.760 watts per property It can dissipate heat.

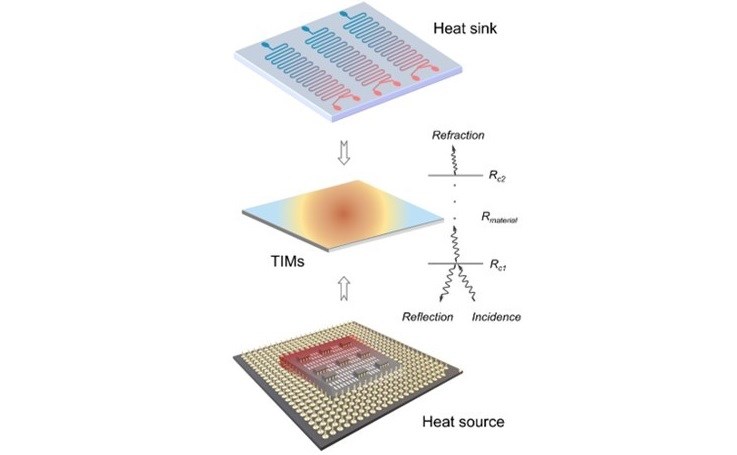

This material provides effective cooling by closing the gap between theoretical heat transfer limits and the performance achieved in real products. Using mechanochemical engineering, liquid metal and ceramic components are mixed in a highly controlled manner, creating gradient interfaces that allow heat to be conducted more easily.

See Full Size

This development means that data centers approximately 8 terawatt-hours of energy per year of consumption 40 percent for cooling only It is a very important step in a world where money is spent. Researchers at the University of Texas say that the TIM they developed is widely used throughout the industry.utma reduces energy needs by 13 percent rate, data center reduce energy consumption by at least 5 percent It is estimated that it can be reduced by This practically means a huge reduction in operational costs and carbon emissions.

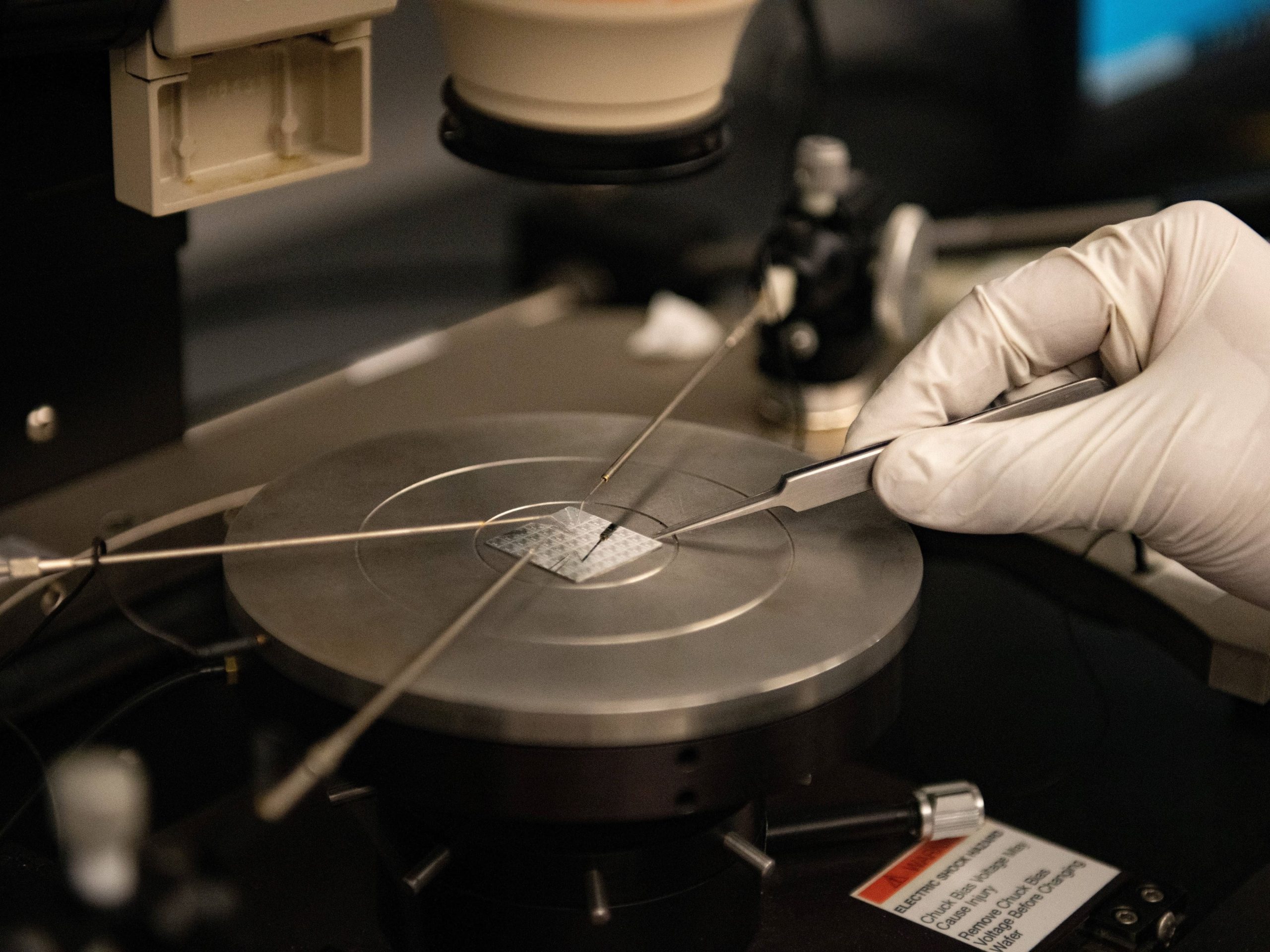

However, there is no definitive information yet about when this material will hit the market. The University of Texas team has only been able to perform small-scale testing at this time, but they are working on large production batches with data center partners for real-world testing. That means this liquid metal thermal paste will be used on large server farms before your home PC.

This news our mobile application Download using

You can read it whenever you want (even offline):