See Full Size

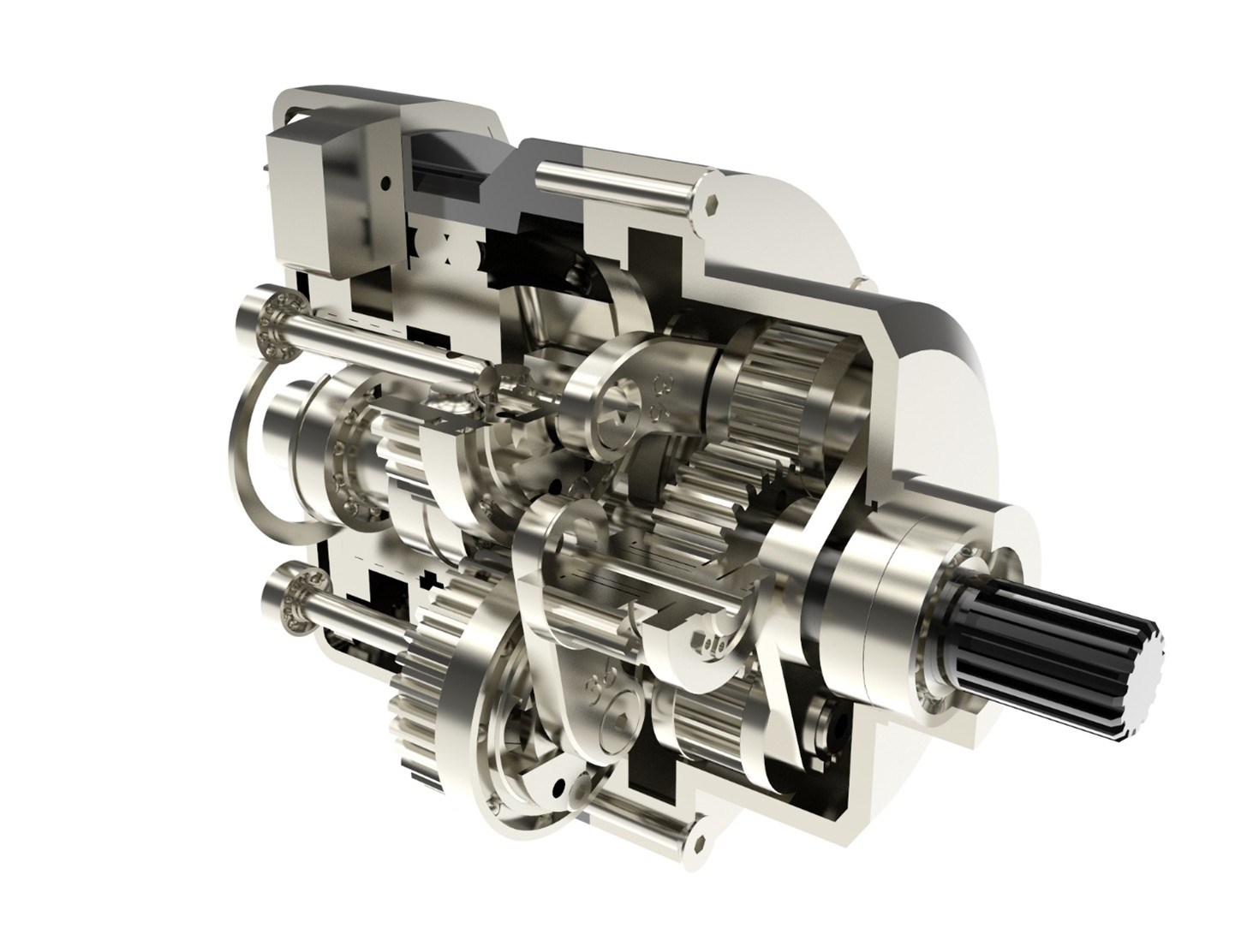

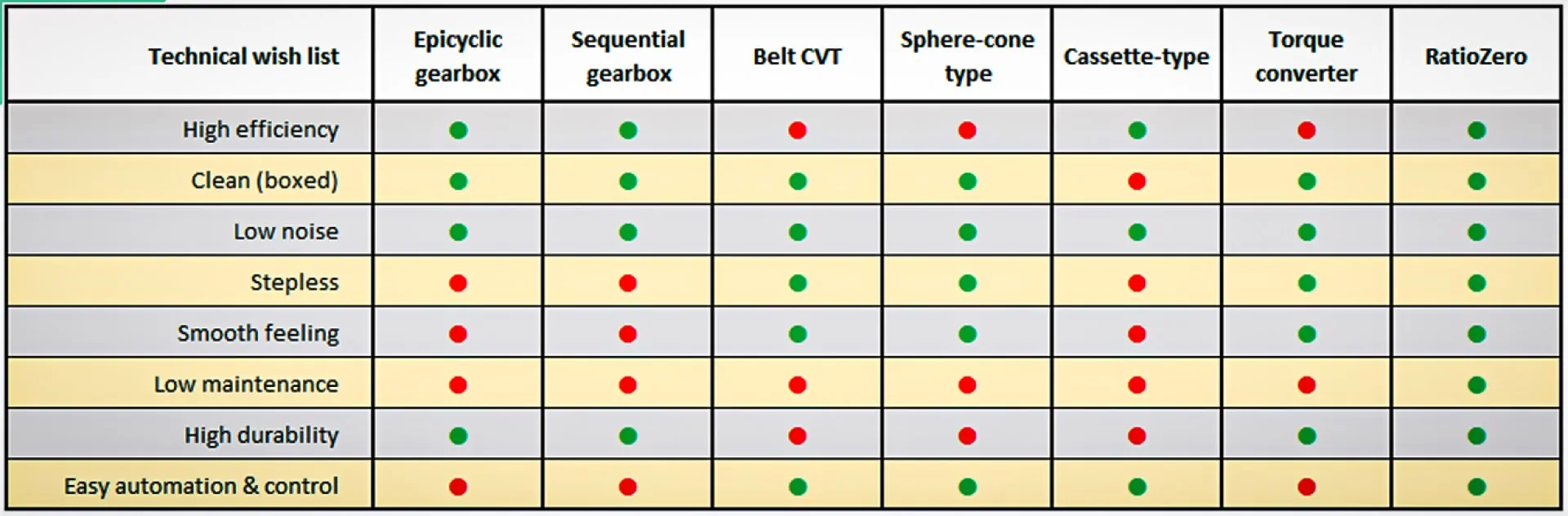

Efficiency of manual transmission meets CVT

Gear CVT combines the biggest advantages of conventional transmissions. Manuel transmissions with gear-to-gear contact 95-98 percent efficiency However, power losses during gear shifting can negatively affect the driving experience. On the other hand, classic CVTs Although it increases engine efficiency by providing smooth and continuous gear changes, it also increases engine efficiency due to friction losses. 70-86 percent efficiency It remains within the range.

See Full Size

How does it work?

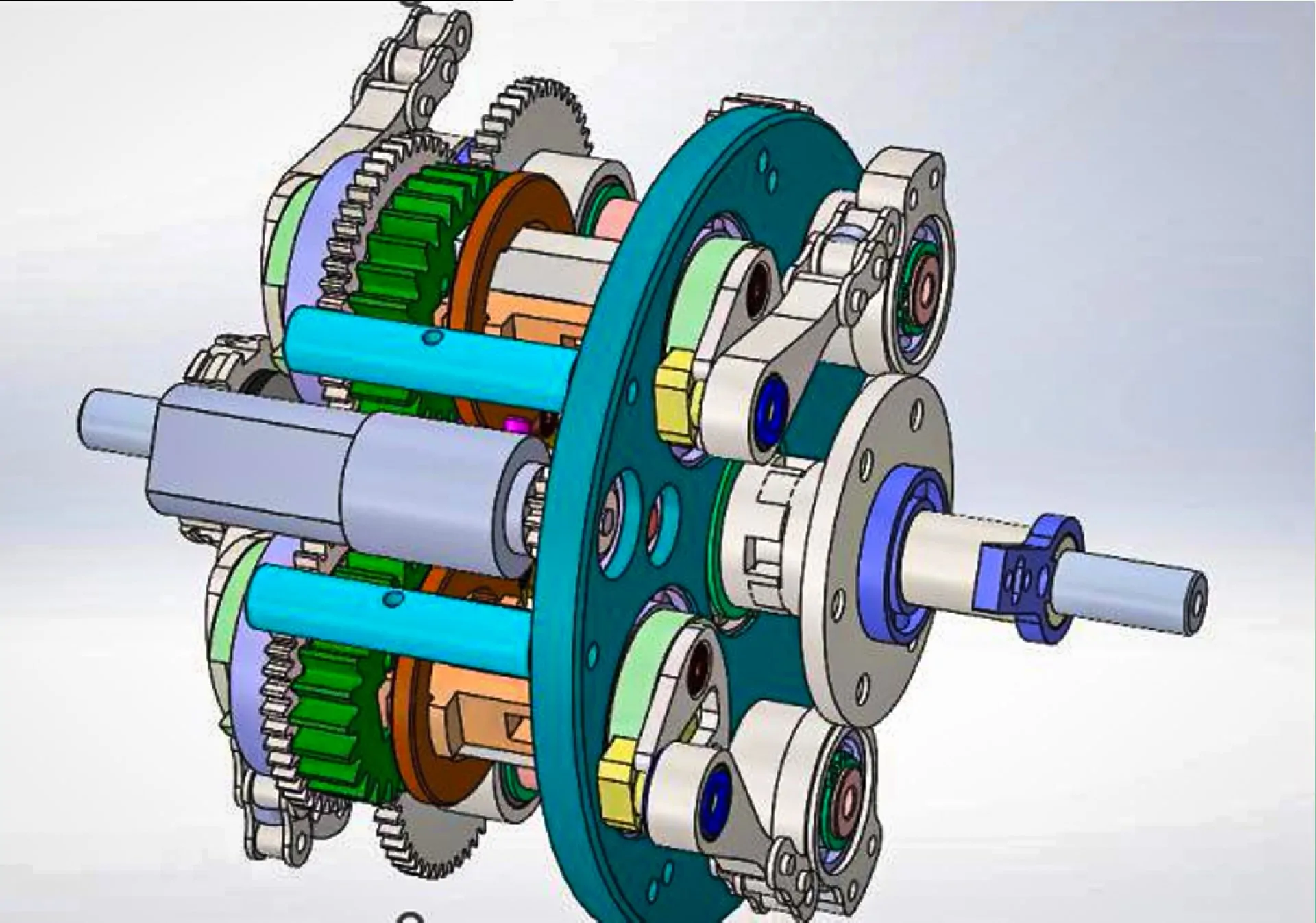

The main innovation of RatioZero is the conventional “fixed ratio gears” begins by stretching the concept. In a standard gear transmission, one gear is directly connected to the other and provides a constant speed ratio. However, RatioZero uses a unique system in which three small gears work alternately. These three gears, in turn, push the output gear from one point, ensuring torque transfer. , then a few teeth are pulled back and prepared to push again. This structure can be thought of as a kind of “torque relay race”, that is, the torque is constantly transmitted to the output.

At the heart of this innovative transmission are three internal gears, each connected to “curved arms”. These arms are mounted on shafts that rotate freely on their own axes. These shafts are also located within a planetary gear system. Motion from the input shaft continuously rotates these “planetary gears”. However, when these shafts are on center, no torque transfer occurs and the transmission remains in “zero ratio” mode; In other words, even when the vehicle comes to a complete stop, the transmission does not lose its power and can operate without the need for a clutch. Thanks to this mechanism, gear ratios are both precisely adjusted and continuously variable. From a technical perspective, this mechanism may not appear to provide a constant throughput rate. However, the developed elliptical gears balance the fluctuations in the input speed and keep the output speed constant.

Where will it be used?

See Full Size

Alter Ego is currently several working prototypes has produced one and even mounted one on a bicycle. The next step will be to connect one of them to the internal combustion engine; The team developed the transmission to further prove the concept. Plans to fit it to a 530cc Yamaha T-Max scooter and then this motorcycle will offer to producers. However, according to the team, the range is very wide; electric bikes, cars, trucks, tractors, industrial machines or wind turbines like.

On the other hand, as those who are familiar with engineering will know, Alter Ego is aware that there are still problems to be solved in its designs. For example, existing fluctuations in torque transmission need to be eliminated. In addition, the mechanical stress created by gear ratios going down to zero should be thoroughly analyzed in terms of durability. For all of these, Alter Ego is at the beginning of the road; The team hopes to move forward in development with sufficient funding support.

Source

https://newatlas.com/automotive/geared-cvt-ratiozero/

https://ratiozero.com/

This news our mobile application Download using

You can read it whenever you want (even offline):